GLASS & MIRRORS - POPULAR MATERIALS IN DESIGN SPACE

In the Construction industry in general, especially Architectural Design and Interior Design in particular, GLASS and MIRROR materials are gradually becoming popular and familiar. Each type has different advantages and disadvantages, characterized by the unique properties of each material. Since then, they have been applied extremely flexibly and reasonably depending on the context, circumstances, and specific characteristics of each type of project. Therefore, through this article, let's join JDesign Co., LTD to learn about "GLASS & MIRRORS - POPULAR MATERIALS IN DESIGN SPACE".

I. Glass:

1. Concept and Production Process:

*) Concept:

Glass is a construction material made from silicate material. The craftsman creates glass by heating silicate blocks until liquefied and shaping them into the desired glass shape. Therefore, glass is defined as a glass product created from a solid solution in amorphous form.

*) The production process of glass includes five steps:

- Cut glass blanks

- Processing on glass blanks

- Wash, dry and inspect

- Heated

- Finished product

2. Classification:

- Regular glass: Transparent glass with basic properties of glass. When broken, it creates dangerous sharp pieces. Normal glass should not be used in places where safety is required. You should only use regular glass to make home decorations, places that do not require soundproofing, heat insulation, etc.

- Laminated safety glass: A type of glass made from many different layers of glass glued together with a PVB film between the layers of glass. If it is glued from tempered glass panels, it will be called tempered laminated glass or safety tempered laminated glass.

Laminated safety glass can be processed and will not crumble, and has good impact resistance. When the glass is broken, it still maintains its original state, the glass fragments will stick to the PVB film, so this is the type of glass with the highest safety. The ability of safety laminated glass to resist "visible intruders" is due to its ability to withstand high impact forces, plus the role of PVB laminated film as a layer of glue that retains small pieces of broken glass and is quite durable. It is difficult to completely remove this layer of glue. Thanks to that, when using laminated safety glass, security is always guaranteed.

Because the production process of safety laminated glass requires high technical requirements and goes through many stages, the cost of laminated glass is higher than that of regular glass.

- Tempered glass: A type of glass whose main component is glass heated at a very high temperature >500 degrees Celsius and then suddenly cooled with gas. This characteristic makes tempered glass very durable and can be used in harsh weather conditions.

The ability to withstand force, impact, load and break due to thermal stress of tempered glass is also outstanding. Low chance of glass being scratched, surface compression resistance up to 10,000 PSI, high safety.

.jpg)

In some cases, tempering the glass can cause the glass to bend as desired. Once the glass is finished, it cannot be processed anymore. If processed, it will break immediately. The outstanding feature of tempered glass when broken is that it does not cause damage. When broken, it will crumble into particles like corn kernels that do not contain sharp edges.

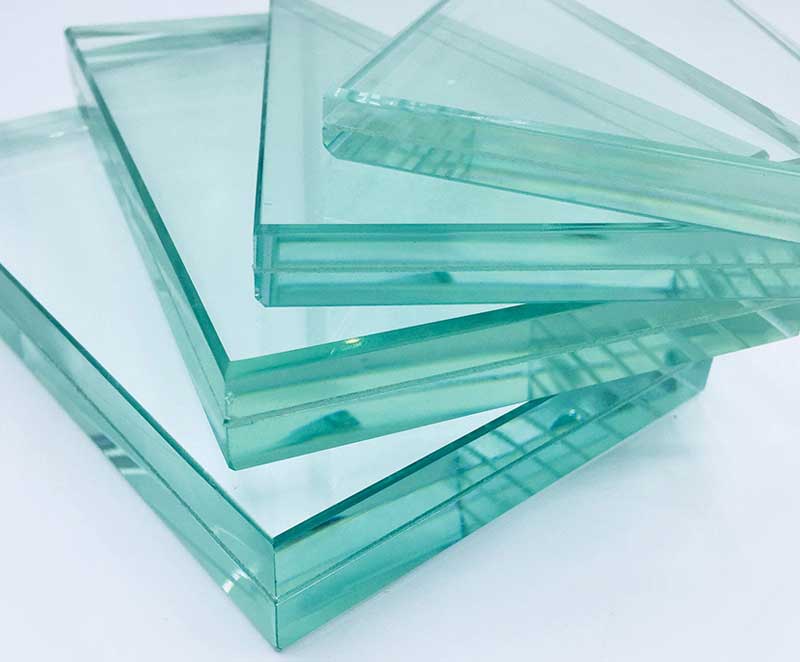

- Box glass: This glass has a box-like structure, usually the outer layer of glass will be tempered glass, reflective glass or Low-E glass. The inner glass layer depends on the customer's needs, the manufacturer will use safety stickers or tempered glass, the space in the middle is filled with Argon gas (inert gas). Therefore, protective glass can reduce noise from the surrounding environment very well, and also increase heat insulation. In addition, the aluminum frame also contains desiccant beads to connect the glass panels together.

Therefore, using box glass helps save energy costs when using air conditioning and lighting systems. Box glass technology is one of the energy-saving glass technologies used for construction projects, especially high-rise buildings. However, the price of boxed glass is quite high due to the technology requirements and many details. Boxed glass is usually twice as heavy as regular glass, requiring a higher-strength frame and hinge system.

- Low-E glass: This type of glass has been widely used around the world thanks to its outstanding properties in reducing heat absorption and heat transmission. This type of glass is coated on the surface with an ultra-thin metalic layer that can slow down heat dispersion and prevent the heat of sunlight.

Between the two layers of glass there is an air space, coated on the surface with a specially selected compound, which helps the glass to emit heat slowly, reducing the dispersion and absorption of heat more slowly. Low-E glass is often used as safety glass for both inner and outer glass layers.

.jpg)

Low-E glass is especially suitable for construction projects in areas with tropical monsoon climates like in Vietnam. Low-e glass protects against heat in the summer and retains heat in the winter. Low-E glass uses magnetic blowing technology to coat one or more layers of metal or special chemicals on the glass surface. Can block surface heat

3. Application:

Nowadays, glass is an indispensable material in construction projects. It is not simply the function of getting light into a space, but also appears in architectural and interior spaces in many different ways and roles to bring different effects.

- Partitions dividing interior space:

Recently, glass partitions have become a new design trend in modern style, especially for young people, to add certain excitement to life. Glass walls can be divided into bedrooms, living rooms, kitchens, etc. Using glass walls to divide rooms not only creates enough private space, but also creates airiness, bringing sophistication and elegance to the house. my house.

There are different types of glass partitions such as: Aluminum frame partitions, wooden frames, iron frames, stainless steel frames... or frameless glass partition systems. Glass partitions are especially popular for use in apartments, modern townhouses, hotels, sea view buildings, etc.

Advantages: Able to penetrate light and withstand external forces well. Glass partitions can choose many different types of glass from normal glass, safety laminated glass, tempered glass, boxed glass... depending on the customer's needs. However, to ensure the best effectiveness of glass partitions, choosing tempered glass partitions is always the top priority because this type of glass is many times harder and more stable than regular glass. Usually has good sound and heat insulation properties.

Disadvantages: Glass partitions usually do not provide absolute privacy because of the transparent material nature of the glass. If cheap glasses are used, the partitions will be of poor quality. Glass partitions are also susceptible to dirt and smudges during use if not cleaned regularly.

- Glass walls surrounding the architecture:

The glass partition surrounding the architecture has a large coverage area and can act as a wall or wall, bringing a sense of spatial connection between the outside and inside of the building.

Advantages: Transparent glass walls, well meeting lighting requirements in the project. Brings a simple, clean, sophisticated beauty. Thanks to its delicate, clear beauty, glass walls are suitable for a variety of different modern architectural styles.

In addition, glass walls surrounding architecture can also be used with other types of aluminum and glass windows. Any house and building should have windows to avoid stuffiness and discomfort. Aluminum and glass windows that open, slide, and slide provide high flexibility along with outstanding features, advantages, and accompanying aesthetics. It is both airy, cool, durable and flexible in different weather conditions.

.jpg)

Disadvantages: In addition to the advantages, glass walls surrounding architecture also have certain disadvantages such as higher cost compared to conventional facade systems, can only be installed in projects with uniform planes and structures. simple design structure. The installation and construction process requires very high technique and precision.

- Stair handrails, railings, ...:

Stair handrails - glass railings are modern style products that are loved and chosen by many customers. Stair handrails - glass railings are quite easy to combine with modern or neoclassical interiors and architectures from tube houses, townhouses to high-end villas, office buildings, etc. ... They bring harmony, luxury, elegance, sophistication and high aesthetics.

Balustrades - glass stair handrails are made of tempered glass or laminated safety glass. But it is usually made of tempered glass because of the safety, rigidity and durability with harsh weather conditions that tempered glass brings.

Advantages: When using stairs, glass railings will help keep the indoor space airy and bright. Furthermore, stairs and glass railings are easy to clean and safe to use. In fact, there are many models of stairs and glass railings for customers to choose from, from herringbone-shaped stairs for large houses to wall-close stairs for narrow houses, circular stairs, spiral stairs, etc.

Disadvantages: In addition to high cost and long construction time, most glass railings and handrails do not have many disadvantages. If you have enough money and time, you will have an extremely sophisticated and luxurious space.

- Decorative glass roof, lighting:

The outdoor glass roof has the ability to completely block rain and sun, and at the same time, the glass has the ability to block UV rays and harmful elements from sunlight for human health. Unlike traditional roofs such as corrugated iron roofs, fipro cement roofs... outdoor glass roofs make the most of natural light sources to help the space always have enough necessary light.

Advantages: The glass roof is highly transparent, does not limit visibility, helping users expand their view of the surrounding scenery. Glass roofs can fit any architectural space, from modern to classic, are highly aesthetic and give the building a luxurious, classy beauty. Cleaning the glass roof is quick, the glass always retains its shine when cleaned.

Disadvantages: The cost of glass roofs is often higher than that of conventional traditional roofs. The glass part of the roof is still at risk of breaking, but the rate is low and when broken, it will also break into small pieces because it is often used mostly tempered glass. Light can penetrate glass, so pay attention to light levels and glass color. At the same time, you must regularly clean the glass to keep it clean to get the best light.

- Car and airplane glass:

Airplane windows in the cockpit are susceptible to direct hits from birds, hail, and foreign objects, so they are more durable and have more layers, but the main material is still plexiglass or similar materials (such as acrylic glass). The passenger window consists of 2 acrylic glass panels, separated by a gap to increase safety and heat insulation.

Windshields are a very important and necessary part of a car. Car glass, in addition to blocking wind, dust and rain, also participates in increasing the rigidity of the vehicle structure and protecting passenger safety in all collision situations.

The structure of a car windshield consists of 2 layers of green-resistant glass. In particular, in between these two layers there is a layer of Polyvinnyl Butyral (PVB) plastic that is pressed tightly together under high pressure and temperature. Thanks to that, when there is a strong impact, the glass breaks into pieces, but the broken pieces still do not fly out, causing danger to people around.

Car door glass are glass panels placed on both sides of the car, on the doors of the car. Car windows are usually made of safety tempered glass, using the tempering method to strengthen the glass for better durability (4 times more effective than regular glass) to ensure passenger safety.

II. Mirror:

1. Concept and production process

*) Concept: A mirror is a sheet that reflects light, made from a layer of plating and covered with a glass plate or other reflecting mirror. The main function of a mirror is to reflect the images of objects or things facing it.

The most familiar type of mirror is a flat mirror, with a flat surface. Curved mirrors (usually convex or concave mirrors) are also used in practice, to enlarge or reduce images, or to focus light or simply distort the reflected image.

Mirrors are often used for makeup (or in other words, "mirror"), decoration, or in architecture and interior design.

Mirrors are also used in scientific equipment such as telescopes, lasers, cameras, and in industrial machines. Most mirrors are designed for visible light; However, mirrors are also designed for other types of waves or wavelengths of electromagnetic radiation, especially in optical devices.

*) Production process:

It can be said that the production process of mirrors also includes 4 steps. For stainless steel mirrors, they are coated with 8 layers of silver, so there will be a clear difference during use.

- Create glass sheet blanks

- Grind and polish the glass surface.

- Apply a reflective layer to the glass

- Quality control

A Belgian mirror is 80% or 90% reflective but can have slight irregularities in the thickness of the glass, like ripples on the surface of water. The image will be slightly distorted, but the distortion will be barely visible to the naked eye. Nowadays, to accurately check whether a mirror meets standards, people use lasers. The laser is pulled across the mirror and checks whether the smoothness of the polishing and the thickness of the mirror meet the standards.

Finally, the finished mirror will be carefully packaged in a shockproof package for transportation to suppliers, distributors and agents.

2. Classification:

- Regular mirror (Belgian mirror):

Belgian mirror is the way Vietnamese consumers call mirror products manufactured, developed according to standards and patented by AGC Flat Glass Europe group (Belgium). Belgian mirrors imported officially in Vietnam are products manufactured at the AGC ASIA PACIFIC PTE LTD factory - Indonesia.

Belgian mirror is coated with silver up to 8 layers, the outside is also covered with a layer of copper and protective paint. This explains the moisture and mold resistance of Belgian mirrors that can last for many years. It is also the only mirror that is immune to the four elements acetic acid, ammonia, salt and humidity. Therefore, it will be the most optimal choice for projects built in salty environments such as coastal areas.

Diverse in size and type:

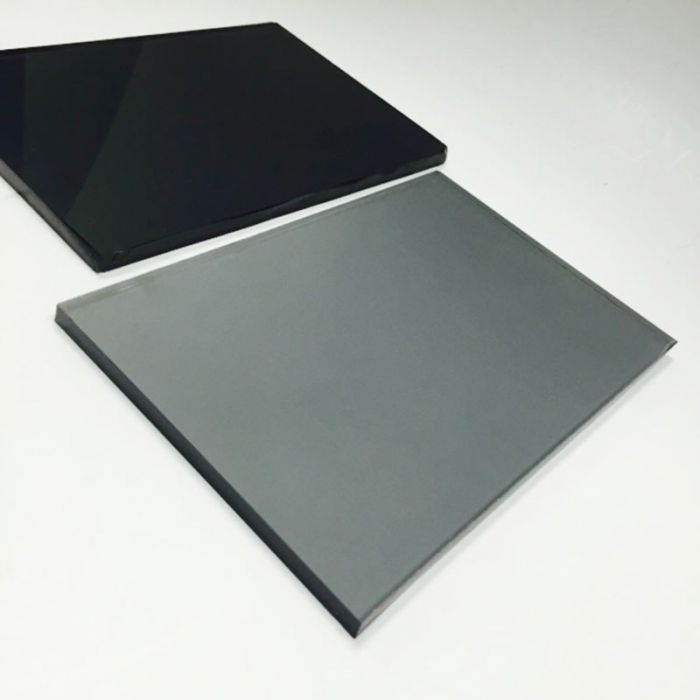

Regarding color: Currently, in addition to traditional white mirrors, there are also Belgian tea mirrors (light tea color) and dark gray Belgian mirrors (Smoky mirrors).

Regarding thickness: The standard Belgian mirror is 5mm, which is considered the optimal thickness to reflect the sharpest image.

About size: The largest Belgian mirror blank size is 2134 x 3048mm. This is also the largest mirror blank size in Vietnam

- Colored mirrors (Tea mirror, smoke gray mirror, black mirror, ...):

Colored mirrors are often made by coating a layer of color on the glass surface. Depending on the production technique, the color of the mirror can be coated on the entire mirror surface or only on a certain part to create patterns and images.

Colored mirrors are a modern trend that helps your living space look more sparkling, magical, and luxurious. Colored mirrors will help the room become colorful and magical without making it too obvious when looking at it.

Tea-colored mirrors, black mirrors, bronze mirrors are often used in living rooms, fashion stores, showrooms, karaoke bars, restaurants, gyms, etc. to create a highlight for the space.

Among mirror models, colored mirrors are highly appreciated for both color and quality. Therefore, it brings many advantages to users such as:

Helps create an expanded effect and increase the area of the living space with excellent light capture ability.

The product is a perfect and unique combination of many small mirror pieces, so it helps users of this mirror line have a more sparkling space.

It doesn't take much time to construct the colored mirror line.

With the main color tones of tea, smoky gray, black, etc., the product is a type of artistic mirror, giving the whole space a warm and mysterious feeling while still maintaining the elegance and class of the house. .

With genuine Belgian mirror material, it ensures users safety and high durability during use.

Regarding feng shui, it brings luck and fortune to the homeowner who installs the product in the right location and destiny.

- Mold-colored mirrors (Moldy tea-colored mirrors, smoky gray, black, ...):

Mold-colored mirrors are used in artistic and luxurious projects, designed into many decorative mirrors for walls, columns, ceilings, etc. The mirror surface is made from high-quality, super-bright Belgian glass. durable.

Mold-colored mirrors are manufactured from high-quality mirror blanks and use modern silver-coating technology, surface color treatment and creating mold patterns with mold-making chemicals. That's why mold-colored mirrors always endure over time and make a difference in large architectural works.

4. Application:

- Wall and ceiling decoration:

Decorative mirrors, wall panels, and ceilings help reflect, making the space more spacious and airy, allowing natural light to be maximized and arranging furniture more easily and conveniently, helping to upgrade the space to become more beautiful. more luxurious and modern.

Advantages: As an interior decoration item to increase the beauty of the house, create a lively highlight and fill the void in your living space. New, unique, durable and beautiful over time.

Disadvantages: Easily breakable is the biggest and only disadvantage of wall and ceiling mirrors. The line of wall and ceiling mirrors has a glass coating made of mainly silver (Belgian, Thai Mirrors) or aluminum (Vietnamese, Chinese, Taiwanese Mirrors), so it cannot be subjected to temperatures of 700 to 1000 degrees Celsius to strengthen them because So wall mirrors are easily broken.

- Production of full-body and makeup mirrors:

Unlike decorative mirrors, full-body and makeup mirrors have the main purpose of looking at the whole body and applying makeup.

Advantages: Using a full-body, makeup mirror allows users to see themselves in a comprehensive, comprehensive way. In particular, this mirror model also reflects images realistically and sharply. For this reason, full-length mirrors are not only used in homes, but are also placed in clothing stores and fashion boutiques.

Disadvantages: Pay attention to reasonable arrangement in each space to suit each function. Do not use too many mirrors in the same space to avoid causing glare and distraction.

- Mirrors for cars, motorbikes, etc.:

Rearview mirrors for cars, motorbikes, etc. are a type of flat mirror used in cars and other vehicles, designed so that the driver can see behind and to the sides through the vehicle's windshield and two car doors.

Advantages: Mirrors mounted on the rearview mirror and both sides of cars and motorbikes will help the driver have a wider field of view. In addition, cars also have rearview mirrors inside the car that can provide a comprehensive view behind. Thanks to the rearview mirror, the driver can see blind spots and limited hidden corners that were previously invisible.

Disadvantages: Limited because depending on each vehicle type, size, and type, different types of suitable mirrors will be chosen. Fragile, especially motorbike mirrors, you should use mirrors that comply with traffic safety laws.

III. Some famous Mirror, Glass and Aluminum Glass brands:

1. Hai Long glass mirror:

2. Viet Nhat glass mirror – VSG:

3. Viglacera glass mirror:

4. Xingfa aluminum and glass

5. Maxpro Japan aluminum and glass:

6. AGC Belgian Mirror:

IV. Summary table of Mirror and Glass classification:

| Numerical order |

Classify |

Characteristic |

Application |

|

|

1 |

Glasses |

Regular glasses |

Glass is a glass product made from an amorphous solid solution. And shaped by cooling the molten silicate mass. Other impurities can be mixed to get the desired product. Under normal conditions, glass is a transparent, relatively hard, hard-to-wear interior material with a very smooth and slippery surface, when broken, it creates dangerous sharp fragments. Normal glass should not be used in places where safety is required. You should only use regular glass to make home decorations, places that do not require soundproofing, heat insulation, etc. |

Using glass as partitions to divide interior spaces, glass walls surrounding architecture or stair handrails, railings, decorative glass roofs, lighting, automobile and airplane glass |

| Safety glasses |

A type of glass made from many different layers of glass glued to the separation between the layers of glass is a PVB film. Can be machined and will not crumble, has good impact resistance. When the glass is broken, it still maintains its original state, the glass fragments will stick to the PVB film, so this is the type of glass with the highest safety. The cost of laminated glass is higher than that of regular glass. |

|||

|

Tempered glass |

Glass is usually heated at very high temperatures >500 degrees Celsius and then suddenly cooled with gas. The ability to withstand force, impact, load and break due to thermal stress of tempered glass is also outstanding. Low chance of glass being scratched, surface compression resistance up to 10,000 PSI, high safety. |

|||

|

Glass box |

Glass has a box-like structure, usually the outer layer of glass will be tempered glass, reflective glass or Low-E glass. Depending on the customer's needs, the manufacturer will use safety stickers or tempered glass, the space in the middle is filled with Argon gas (inert gas). Can reduce noise from the surrounding environment very well, also increases heat insulation. Box glass technology is one of the energy-saving glass technologies used for construction projects, especially high-rise buildings. |

|||

|

Low-E Glass |

Low-E glass is often used as safety glass for both inner and outer glass layers. Between the two layers of glass there is air space. Outstanding properties in reducing heat absorption and heat transfer. Low-E glass is especially suitable for construction projects in areas with tropical monsoon climates like in Vietnam. Low-e glass protects against heat in the summer and retains heat in the winter. |

|||

|

2 |

Mirror |

Ordinary mirror |

A mirror is a sheet that reflects light, made from a layer of plating and covering a sheet of glass or other reflecting mirror. The main function of a mirror is to reflect the images of objects or everything facing it. Belgian mirrors are coated with up to 8 layers of silver, the outside is also covered with a layer of copper and protective paint. This explains the moisture and mold resistance of Belgian mirrors that can last for many years. |

Use mirrors to decorate walls and ceilings. Use as full-length mirrors or makeup mirrors. Mirrors for cars, motorbikes,... |

|

Color mirror |

Colored mirrors are made from regular mirrors and coated on the surface with a layer of color. Depending on the production technique, the color of the mirror can be coated on the entire mirror surface or only on a certain part to create patterns and images. Colored mirrors are highly appreciated for both color and quality. Therefore, it brings many advantages to users. |

|||

|

Musty colored mirror |

Mold-colored mirrors are manufactured from high-quality mirror blanks and use modern silver-coating technology, surface color treatment and creating mold patterns with mold-making chemicals. Used in artistic and luxurious projects, designed into many decorative mirrors for walls, columns, ceilings, etc. The mirror surface is made from high-quality Belgian glass, super bright and durable. |

|||

Today, Glass and Mirrors are commonly used everywhere because of their outstanding properties and advantages. There is no limit to the function or location of use. Especially in the interior design and construction industry, architecture is even more favorable for use in different locations, from main works to auxiliary works. Above is the information that JDesign Co., LTD provides about Glass - Mirrors & Popular Materials in the design space. Hopefully this article will help you have an overall view to choose more suitable products in deciding to use materials from Glass and Mirrors for your Architectural and Interior Space!

-----------------------------------------------------

JDesign Co., LTD - PROVIDE PACKAGE SOLUTION RELATED TO INTERIOR DESIGN AND CONSTRUCTION!

Contact us now to schedule a Free Consultation/Survey/Quote!

Product warranty up to 03 years – Commitment to product maintenance for life!

For more details please contact:

- Email: contact.jdesignvn@gmail.com

- Tel: (+84) 866.648.298

- Website: https://j-design.vn/

- Fanpage: https://www.facebook.com/jdesignvn

- Corporate Office: 03/50 Nguy Nhu Kon Tum, Nhan Chinh, Thanh Xuan, Ha Noi

JDesign - Your Inspiration. Our Creation!

#jdesignvn #interior #interiordesign #interiordecor #glasses #mirror