VENEER - APPLICATION OF USING WOOD MATERIALS IN INTERIOR

Today, Veneer is known as a natural wood material, widely used in the Furniture industry. Bringing exquisite beauty, high perfection, sharpness and luxury to Interior products.

So let's find out what Veneer material is? What are the advantages and disadvantages of Veneer? What is the application of Veneer in the Furniture industry? Please follow the article below from JDesign Co., LTD to better understand this type of industrial wood material!

I. Introduction to Veneer:

1. General introduction:

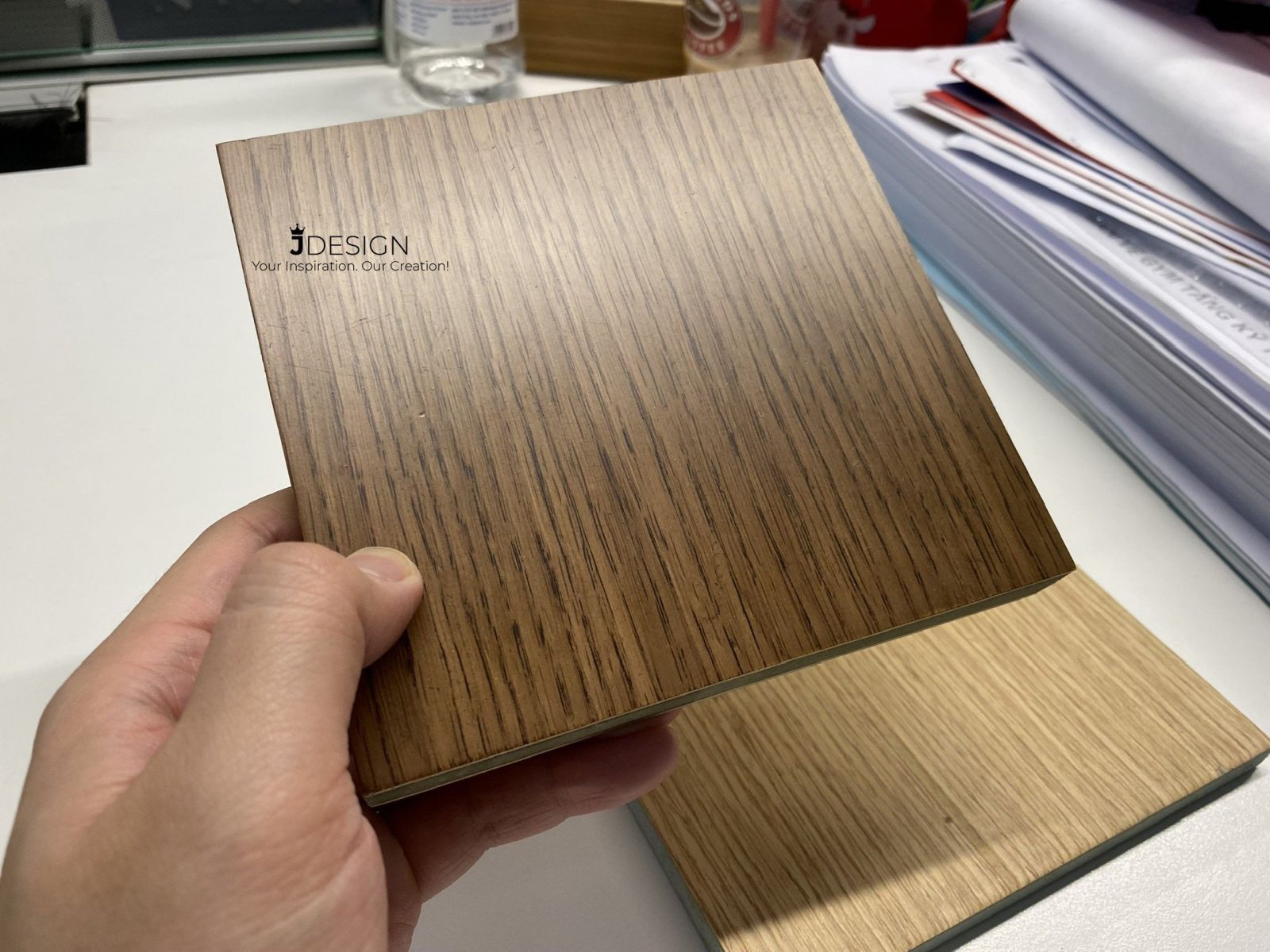

Veneer is understood as a thin board, made from natural wood such as Walnut, Oak, Sapeli, Ash,... with a thickness usually about 0,3 - 0,6mm.

Veneer is often processed and covered/glued onto industrial wood cores such as MDF, HDF, Plywood, Composite,... to create Veneer wood panels that are both high quality and highly aesthetic with a wood-like appearance. nature. Therefore, the special point about Veneer is that although it originates from natural wood, Veneer Wood Interior products do not belong to the Natural Wood Interior line.

The introduction of Veneer material is an optimal solution to protect forest and precious wood resources in countries because from one natural wood tree (flesh wood) many Veneer boards can be cut.

2. Popular types of Veneer:

2.1. Oak Veneer:

These are Veneer panels made from natural Oak, including two types: White Oak and Red Oak, originating mainly from America and Europe.

Oak Veneer is easy to cut and shape, helping to create exquisite Interior Designs. In addition, this type of wood also contains a number of compounds that are waterproof, helping to resist rot and termites better than some other types of wood.

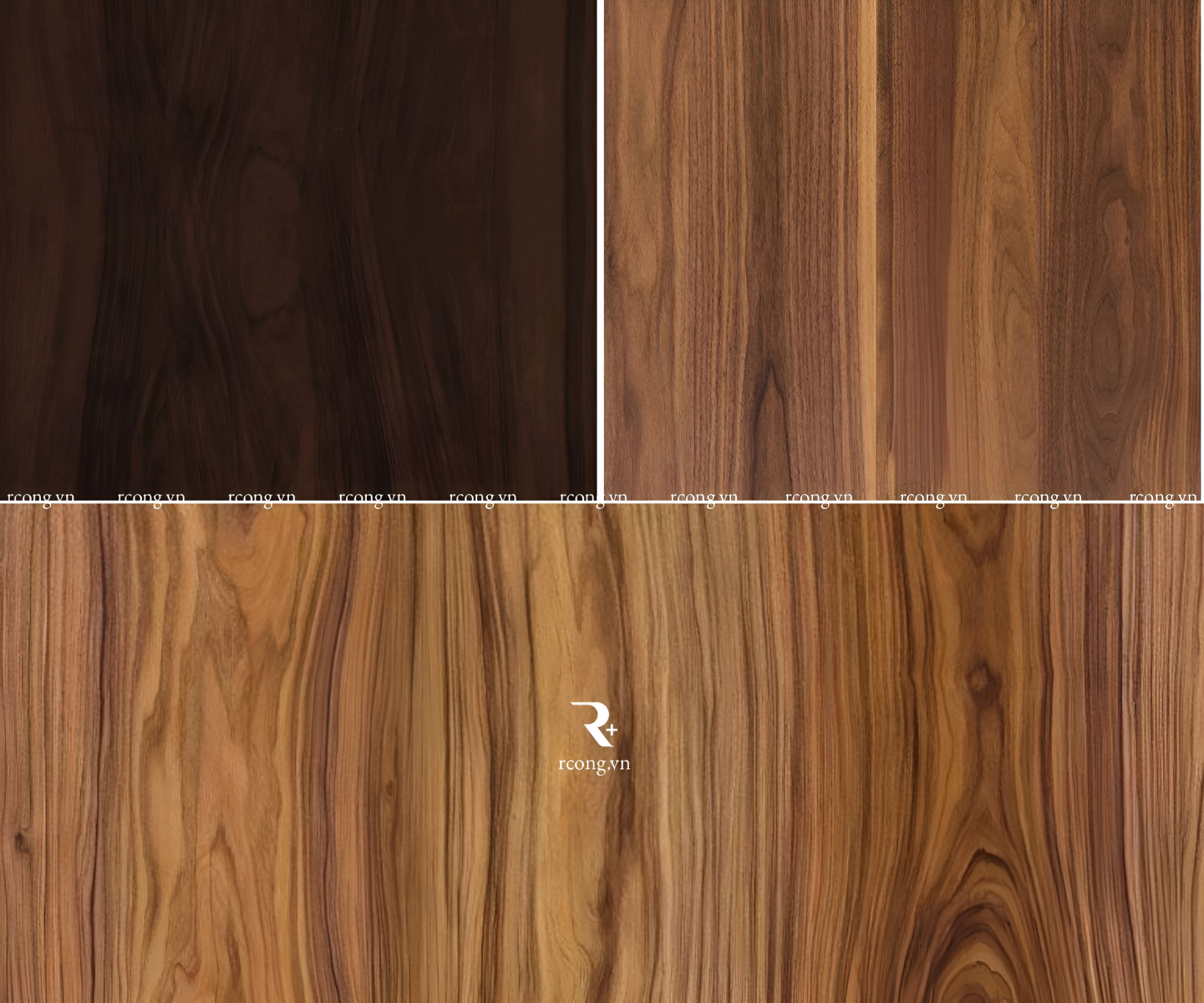

2.2. Walnut Veneer:

Veneer panels are thinly sliced from Walnut, often popular with light colors such as creamy white to dark light brown or chocolate brown.

Walnut veneer has good heat resistance, strength and moisture resistance. Along with that, the material is extremely aesthetic and environmentally friendly.

2.3. Sapeli Veneer:

Veneer panels are thinly sliced from Sapeli, often with bright, even colors, the common color range is from light red to dark red.

Sapeli Veneer minimizes the possibility of termites, warping, and shrinkage.

2.4. Ash Veneer:

Veneer panels are thinly sliced from ash wood, usually with a wood color ranging from light to almost white.

Ash Veneer is effectively resistant to warping, is not affected by weather and is suitable for the climate in Vietnam.

II. Veneer Material Production Process:

To form a complete Veneer wood panel, the production process usually includes the following 7 steps:

Step 1: Choose suitable solid wood such as Walnut, Oak, Sapeli, etc. They must be of good quality and minimize deep knots in the wood. Then basic processing such as peeling, soaking to remove resin, and drying.

Step 2: Spread the wooden block into thin slices with a thickness of about 0,6mm to 3mm.

Step 3: The thin wood slices are placed in the dryer to remove remaining moisture. Absolutely do not expose to natural sunlight because high temperatures will cause the wooden slices to warp and break easily.

Step 4: Apply glue to the surface of industrial wood such as MDF, HDF, Plywood, etc. Then apply Veneer to the surface that has just been coated with glue. The type of glue commonly used in this process is UF. With the main ingredient NH4CL, they will quickly become a solid and hard compound after being annealed and heat bonded.

Step 5: Press the Veneer onto the wooden core board. Normally, people will press these two layers together using a hot press or cold press. This process is performed automatically using a specialized press.

Step 6: After fixing the Veneer part on the wooden core, people will sand and polish to create a flat and smooth product.

Step 7: Finish the surface of the Veneer panel with PU paint or oil to create the finished product color.

Step 8: Pack, prepare for transportation, distribution and installation.

III. Advantages and Disadvantages of Veneer in Interior Design:

1. Advantages:

1.1. Diversity of Colors and Designs:

Even though it goes through the processing process, the true nature of the Veneer material is still natural wood, so the product surface will have very realistic wood grain and color. Besides, the Color Palette and Design of Veneer materials are also quite diverse, so it can meet the needs of many customers as well as suit many different Interior Design styles.

1.2. Saving natural resources:

Veneer is created by peeling thin layers from wood, allowing for the use of a smaller amount of wood material than when using solid wood. This helps protect forests and reduces pressure on natural wood supplies.

After a period of use, Veneer can also be recycled by crushing to use as a raw material for the production of industrial boards. This helps reduce the amount of waste released into the environment, while supporting a recycling and sustainable economic model.

1.3. Flexibility in Design and Choice:

The variety of colors of Veneer materials can suit many different design styles, from traditional, classic to modern. In addition, the bending ability of Veneer material also allows creating products with more complex shapes than using solid wood and other types of industrial wood. Therefore, Veneer materials are increasingly popular and used to create countless Interior products with different designs and styles such as doors, decorative panels, wardrobe, ...

2. Disadvantages:

2.1. High price:

Veneer materials are often made from thin layers of precious woods such as Walnut wood, Oak wood, etc. The production process requires high technique and layer cutting technology, so finished products made from Veneer often have high prices. than other industrial wood products on the market.

2.2. Poor surface scratch resistance:

Veneer panels have a very thin thickness and are naturally natural wood, so their scratch resistance during use is not high.

IV. Applications of Veneer wood in Interior Design:

Nowadays, Veneer materials are increasingly popular and widely used in the field of Interior Design and Construction. Below are some popular Furniture products made from Veneer materials:

1. Door:

Veneer-covered MDF/Plywood core wooden doors are one of the most popular and trusted types of wooden doors on the market.

The advantages of MDF/Plywood doors covered with Veneer are excellent sound insulation, smooth operation, shrink resistance, and are not affected by weather, climate, humidity, and temperature factors. high aesthetic.

2. Decorative cladding:

MDF/Plywood wall panels covered with Veneer are currently still the leading trend in the field of Interior Design and Construction. Because it not only helps bring a luxurious and classy space but is also more environmentally friendly than natural wood wall panels.

3. Wardrobe:

MDF/Plywood cabinets and wardrobes covered with Veneer always have a smooth, bright surface, resistant to warping, termites and cracking well when the weather changes. In addition, depending on customer needs, Veneer wooden cabinet surfaces can also have delicate grain patterns without fear of fading under the influence of time.

The use of industrial wood materials, especially Veneer materials in the Interior industry is not only a modern Design Trend but also brings many outstanding advantages. Veneer materials not only bring natural beauty and warmth to living spaces but also help save natural resources and contribute to environmental protection.

With a variety of colors, textures and designs, Veneer Materials are gradually becoming a wood material favored by Interior Design and Construction Units as well as becoming the top choice of many customers. .

Above is useful information that JDesign Co., LTD provides about: "Veneer - Application of using wood materials in Interior". Hopefully this article will help you have an overall view of Veneer Materials to make the most accurate decision to choose the right product for your space.

JDesign Co., LTD is proud of being a professional Interior Design and Construction Company. We are confident to always bring to our customers the complete Interior Design and Construction solution with the best designs and the latest trends, besides the quality of completing the Project with the most reasonable time. with the most economic cost, always accompanied by the condition of product maintenance support during and after the best project handover time to customers!

-----------------------------------------------------

JDesign Co., LTD - PROVIDE PACKAGE SOLUTION RELATED TO INTERIOR DESIGN AND CONSTRUCTION!

Contact us now to schedule a Free Consultation/Survey/Quote!

Product warranty up to 03 years – Commitment to product maintenance for life!

For more details please contact:

- Email: contact.jdesignvn@gmail.com

- Tel: (+84) 866.648.298

- Website: https://j-design.vn/

- Fanpage: https://www.facebook.com/jdesignvn

- Corporate Office: 03/50 Nguy Nhu Kon Tum, Nhan Chinh, Thanh Xuan, Ha Noi

JDesign - Your Inspiration. Our Creation!

#jdesignvn #interior #interiordesign #interiordecor #veneer